Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 02 abril 2025

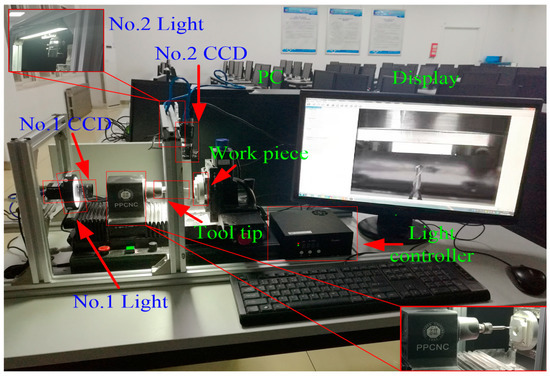

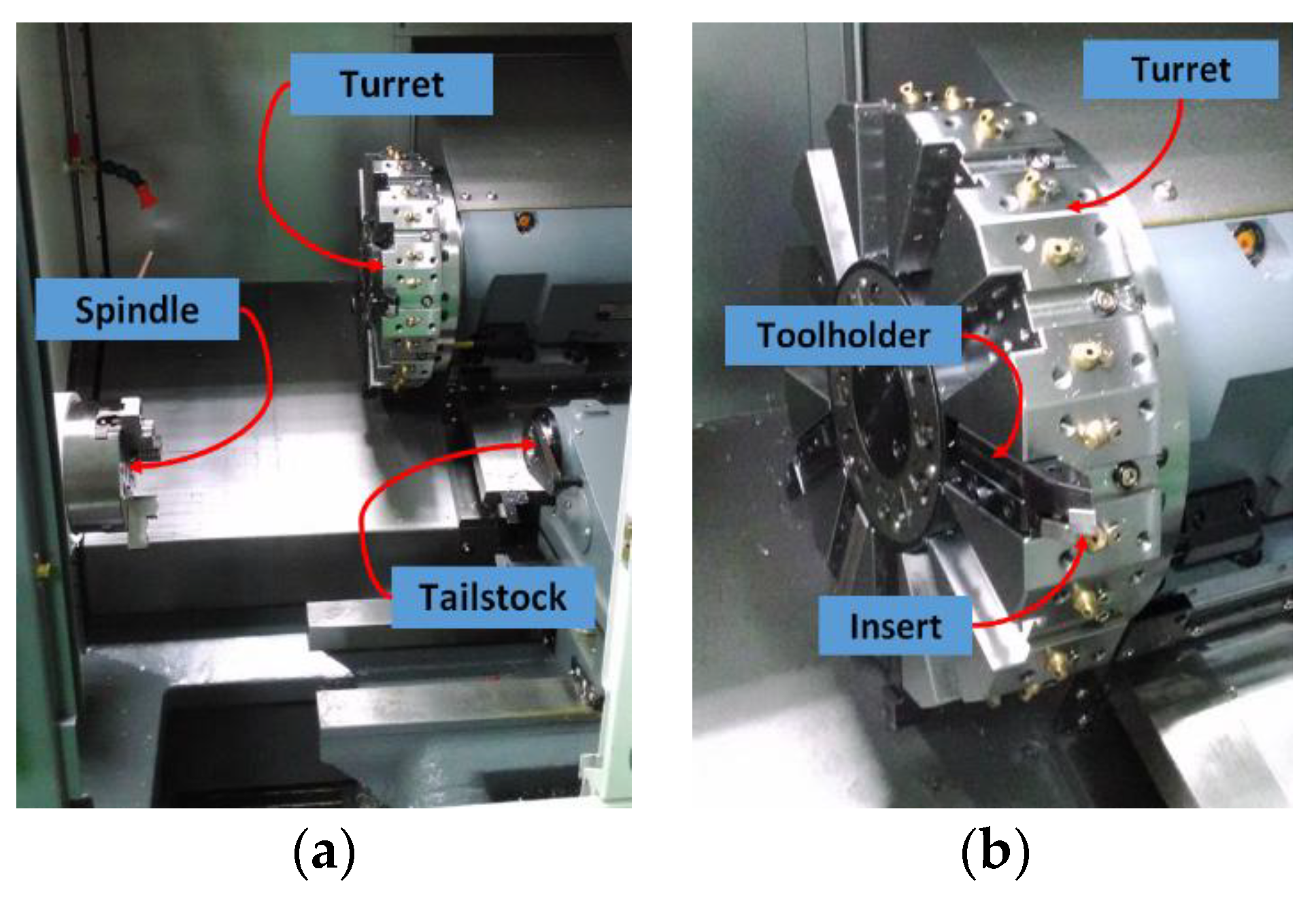

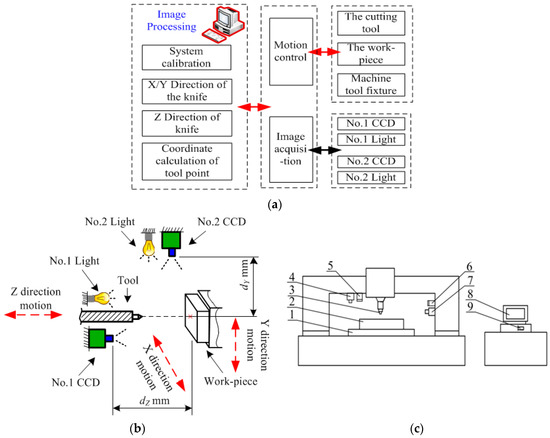

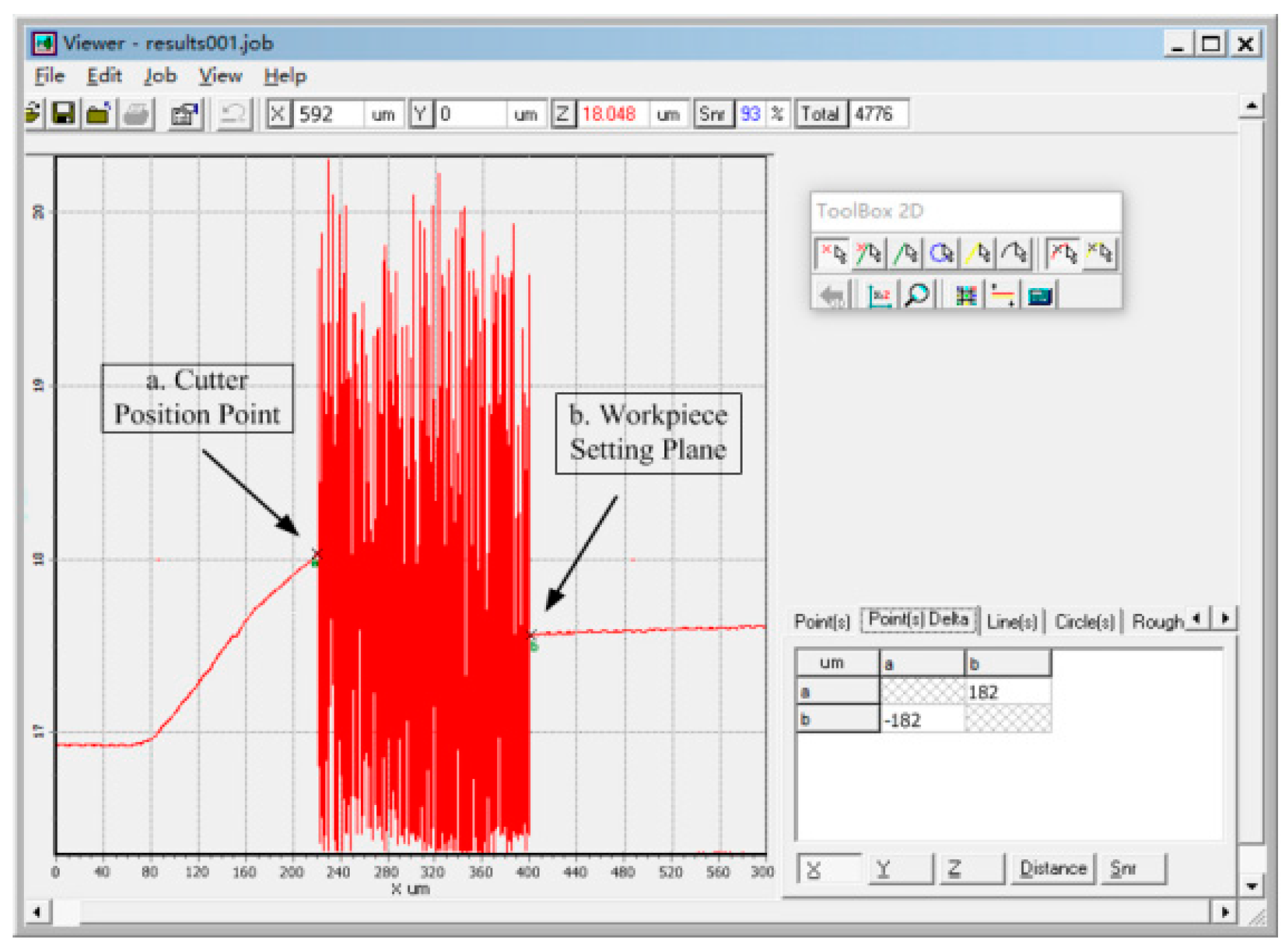

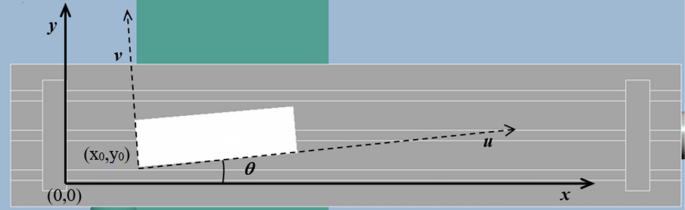

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

A backyard factory: How robots empower you to create your own

Sensors, Free Full-Text

Practical Considerations for Custom CNC Machining - The

OPT Machine Vision_SCI Machine Vision_Lights_Lenses_Cameras

Machine learning and artificial intelligence in CNC machine tools

Materials, Free Full-Text

A critical review for machining positioning based on computer

Sensors, Free Full-Text

Sensors, Free Full-Text

Development of a computer vision-based system for part referencing

Recomendado para você

-

F100 Unibody This is one of the worst things, I have seen02 abril 2025

F100 Unibody This is one of the worst things, I have seen02 abril 2025 -

Classic Truck Performance02 abril 2025

-

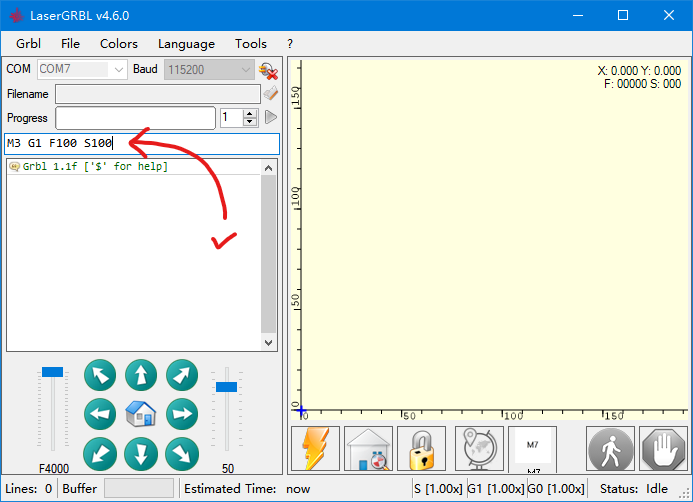

How to Test Laser at GRBL – NEJE02 abril 2025

How to Test Laser at GRBL – NEJE02 abril 2025 -

Porsche Guards Red, 80K / 84A / M3A / G1 / G802 abril 2025

Porsche Guards Red, 80K / 84A / M3A / G1 / G802 abril 2025 -

Tấm Flat 100mm F100-G1 - HNC Deco Moulding02 abril 2025

Tấm Flat 100mm F100-G1 - HNC Deco Moulding02 abril 2025 -

F-100D SUPER SABRE TYPE G-1 LOAD METER02 abril 2025

F-100D SUPER SABRE TYPE G-1 LOAD METER02 abril 2025 -

1 2 Abs Fittings02 abril 2025

1 2 Abs Fittings02 abril 2025 -

Nikon F100 Review in 2023 - 35mm SLR Film Camera02 abril 2025

Nikon F100 Review in 2023 - 35mm SLR Film Camera02 abril 2025 -

Thermaltake Pacific DIY LCS Black G1/4 PETG 16mm (5/802 abril 2025

Thermaltake Pacific DIY LCS Black G1/4 PETG 16mm (5/802 abril 2025 -

Lona Freio F100 67/78 Traseiro02 abril 2025

Lona Freio F100 67/78 Traseiro02 abril 2025

você pode gostar

-

Pin by Jujuba de Limão 💚 on Majin Sonic x Lord X02 abril 2025

Pin by Jujuba de Limão 💚 on Majin Sonic x Lord X02 abril 2025 -

Call of Duty: Vanguard - Todas as novidades, funcionalidades PS502 abril 2025

Call of Duty: Vanguard - Todas as novidades, funcionalidades PS502 abril 2025 -

Hikari no densetsu, Tome 1 (French Edition) by Izumi Asō02 abril 2025

Hikari no densetsu, Tome 1 (French Edition) by Izumi Asō02 abril 2025 -

EU online gambling regimes - Ten years on - Clifton Davies Consultancy Ltd.02 abril 2025

EU online gambling regimes - Ten years on - Clifton Davies Consultancy Ltd.02 abril 2025 -

Is It Time For My Hero Academia To Really Kill Off Some Major Characters?02 abril 2025

Is It Time For My Hero Academia To Really Kill Off Some Major Characters?02 abril 2025 -

Rick And Morty Drunk Rick Sanchez GIF02 abril 2025

Rick And Morty Drunk Rick Sanchez GIF02 abril 2025 -

New Megas Have Been Added To The Pokémon GO Code02 abril 2025

New Megas Have Been Added To The Pokémon GO Code02 abril 2025 -

Black Bullet está 8 anos e meio em hiato, e não há sinal de vida do autor02 abril 2025

Black Bullet está 8 anos e meio em hiato, e não há sinal de vida do autor02 abril 2025 -

KOF 97 Combos destruidores e infinitos02 abril 2025

KOF 97 Combos destruidores e infinitos02 abril 2025 -

Vestidos de noiva inspirados em princesas da Disney02 abril 2025

Vestidos de noiva inspirados em princesas da Disney02 abril 2025