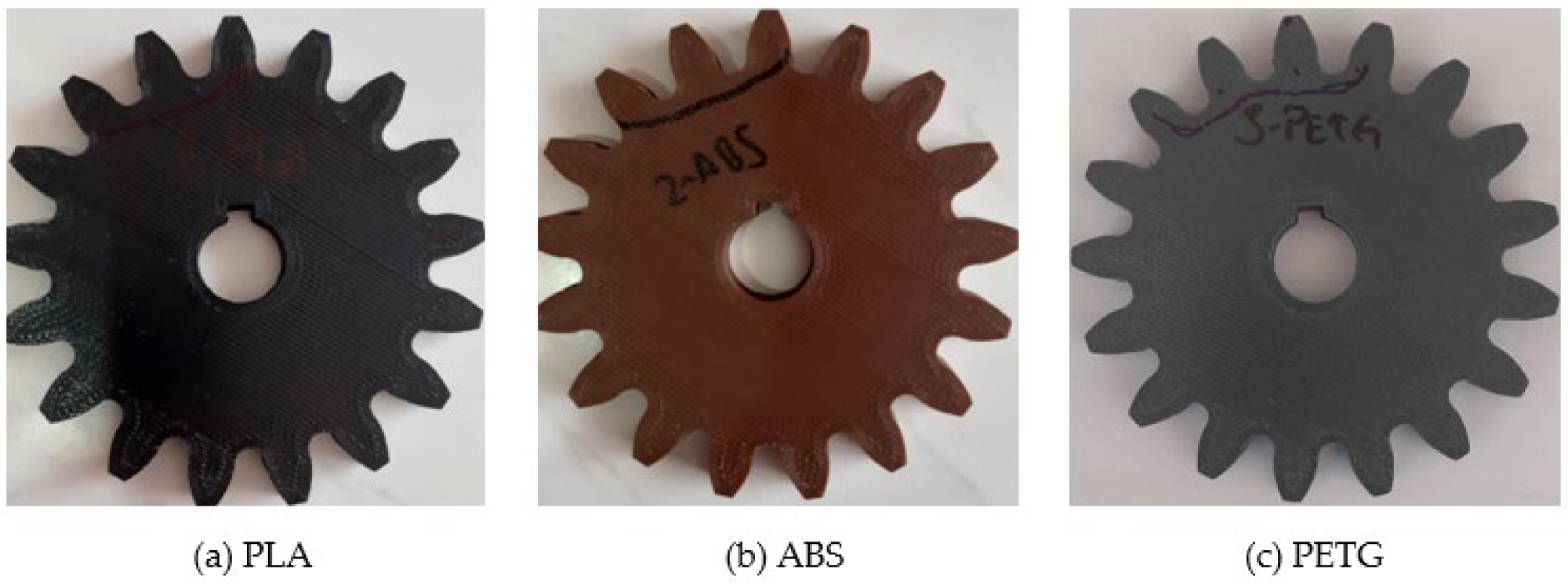

Making Extremely Wear-Resistant Plastic Gears with 3D Printing

Por um escritor misterioso

Last updated 21 março 2025

Using SLS with iglidur® high-performance polymers developed by igus allows manufacturers to make customized plastic gears.

How To Succeed When 3D Printing With Nylon

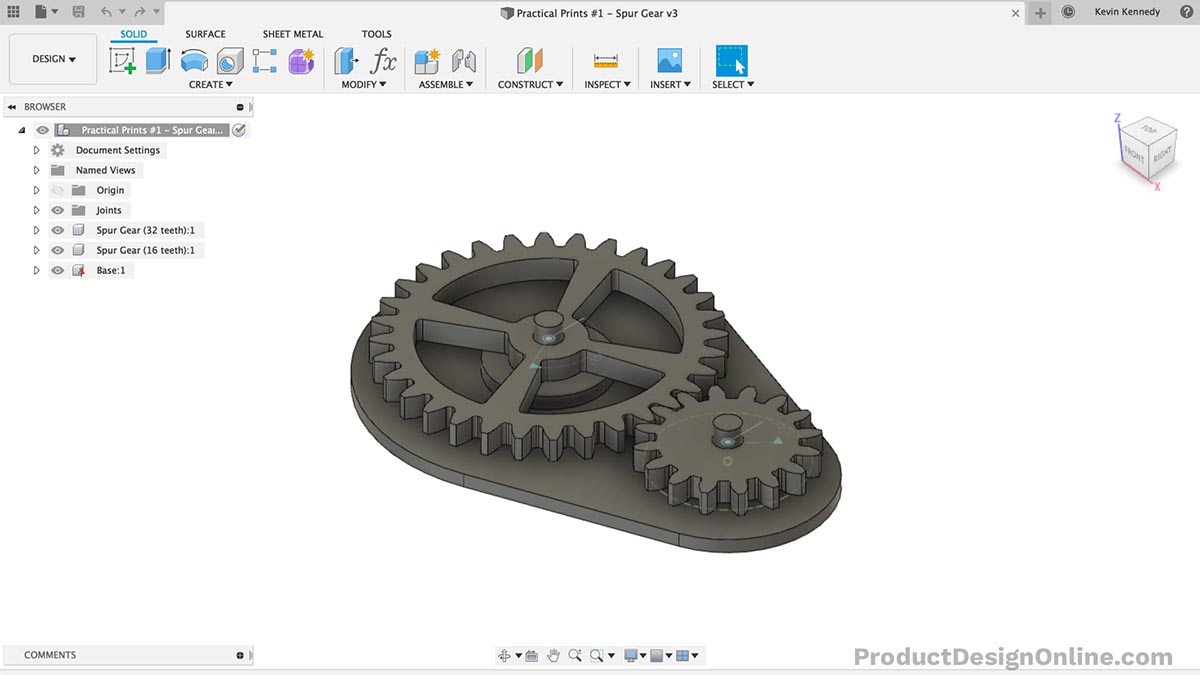

Create Custom 3D Printable Gears in Fusion 360

Nylon 3D Printing: All you Need to Know - AMFG

The Use of Plastic Gears in Industries

How To 3D Print Gears Like A Pro - 7 Design Tips and Advice

3D Printed Gear Serves Seven Months Hard Labor

OVERTURE Nylon Filament 1.75mm 3D Printer Filament, Polyamide (PA) 1kg Spool (2.2lbs), Dimensional Accuracy +/- 0.03 mm, Fit Most FDM Printer (Black) : Industrial & Scientific

Improving the performance of 3D printed gears : r/3Dprinting

Guide to SLS Post-Processing Techniques: Media Blasting, Smoothing, Coating, Coloring, and More

Recomendado para você

-

Who Invented Gears?21 março 2025

Who Invented Gears?21 março 2025 -

Skill Builder: Learn The Types Of Gears - Make21 março 2025

Skill Builder: Learn The Types Of Gears - Make21 março 2025 -

File:Gears.png - Wikipedia21 março 2025

File:Gears.png - Wikipedia21 março 2025 -

258,400+ Gears Stock Illustrations, Royalty-Free Vector Graphics21 março 2025

258,400+ Gears Stock Illustrations, Royalty-Free Vector Graphics21 março 2025 -

Plastic Gears: Design, Materials, Types, Advantages, and Disadvantages21 março 2025

Plastic Gears: Design, Materials, Types, Advantages, and Disadvantages21 março 2025 -

Learning Resources Gears! Gears! Gears! Cycle Gears21 março 2025

Learning Resources Gears! Gears! Gears! Cycle Gears21 março 2025 -

Gear Definition & Meaning21 março 2025

Gear Definition & Meaning21 março 2025 -

Spur Gears - QTC Metric Gears21 março 2025

Spur Gears - QTC Metric Gears21 março 2025 -

51,185 Gears Stock Photos - Free & Royalty-Free Stock Photos from21 março 2025

51,185 Gears Stock Photos - Free & Royalty-Free Stock Photos from21 março 2025 -

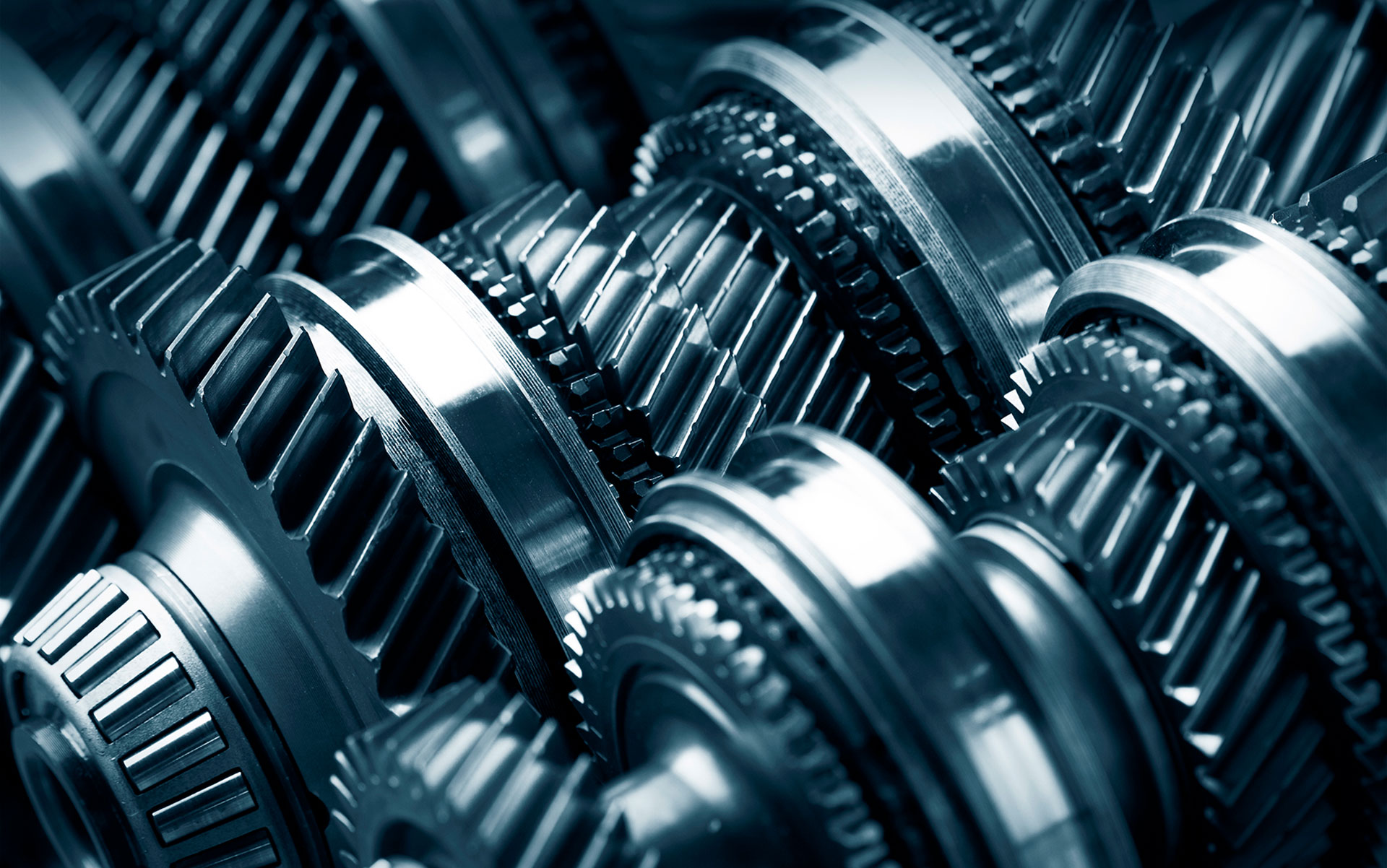

Thinking beyond rolling bearings: gears - Evolution21 março 2025

Thinking beyond rolling bearings: gears - Evolution21 março 2025

você pode gostar

-

How To Get Every New Accessories21 março 2025

How To Get Every New Accessories21 março 2025 -

Jeanne . Anime, Animes , Personagens de anime, Jeanne Vanitas HD21 março 2025

Jeanne . Anime, Animes , Personagens de anime, Jeanne Vanitas HD21 março 2025 -

Download Mod Lucky block minecraft PE on PC (Emulator) - LDPlayer21 março 2025

-

China x Coreia do Sul Jogos Olímpicos 2024 - Qualificação21 março 2025

China x Coreia do Sul Jogos Olímpicos 2024 - Qualificação21 março 2025 -

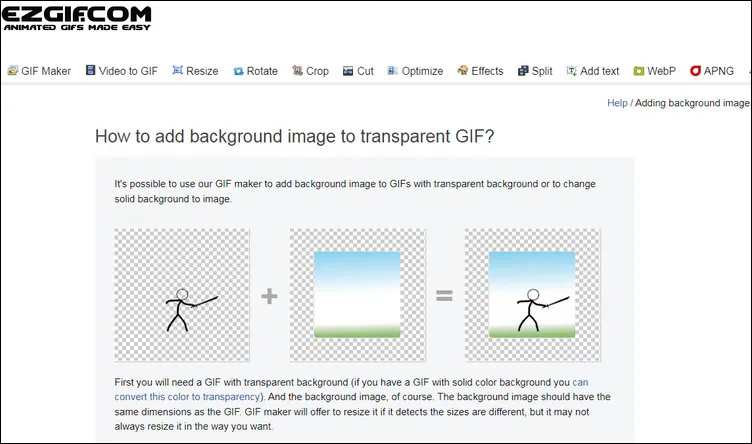

How to Add Background to A Transparent GIF Online for Free21 março 2025

How to Add Background to A Transparent GIF Online for Free21 março 2025 -

BLINDERS Cambridge İngilizce Sözlüğü'ndeki anlamı21 março 2025

BLINDERS Cambridge İngilizce Sözlüğü'ndeki anlamı21 março 2025 -

Billiard for Android - Download the APK from Uptodown21 março 2025

-

Considerado esporte de salão, o futebol de botão reúne gerações em torno do tabuleiro, Divirta-se mais21 março 2025

Considerado esporte de salão, o futebol de botão reúne gerações em torno do tabuleiro, Divirta-se mais21 março 2025 -

2010s Anime Series Tier List (Community Rankings) - TierMaker21 março 2025

2010s Anime Series Tier List (Community Rankings) - TierMaker21 março 2025 -

![Artist: Toby Fox [Composer] - OC ReMix](https://ocremix.org/thumbs/180/files/images/artists/toby-fox-2598.png) Artist: Toby Fox [Composer] - OC ReMix21 março 2025

Artist: Toby Fox [Composer] - OC ReMix21 março 2025